The Comprehensive Guide to Metal Casting: Techniques, Applications, and Industry Insights

Metal casting is one of the oldest and most versatile manufacturing processes used across industries. From automotive parts to aerospace components, metal casting plays a pivotal role in creating complex shapes with precision and efficiency. This technique involves pouring molten metal into a mold, allowing it to cool, and then removing the solidified piece for further processing.

The significance of metal casting in modern manufacturing cannot be overstated. It offers a cost-effective solution for producing intricate designs that would be challenging or impossible to achieve with other manufacturing methods. The efficiency and adaptability of metal casting make it an indispensable tool in industries ranging from construction to electronics.

In the initial stages of metal casting, selecting the right materials, molds, and techniques is crucial. This choice directly impacts the quality, durability, and performance of the final product. As such, understanding the fundamentals of metal casting is essential for engineers, designers, and manufacturers aiming to optimize production and reduce costs.

The Fundamentals of Metal Casting

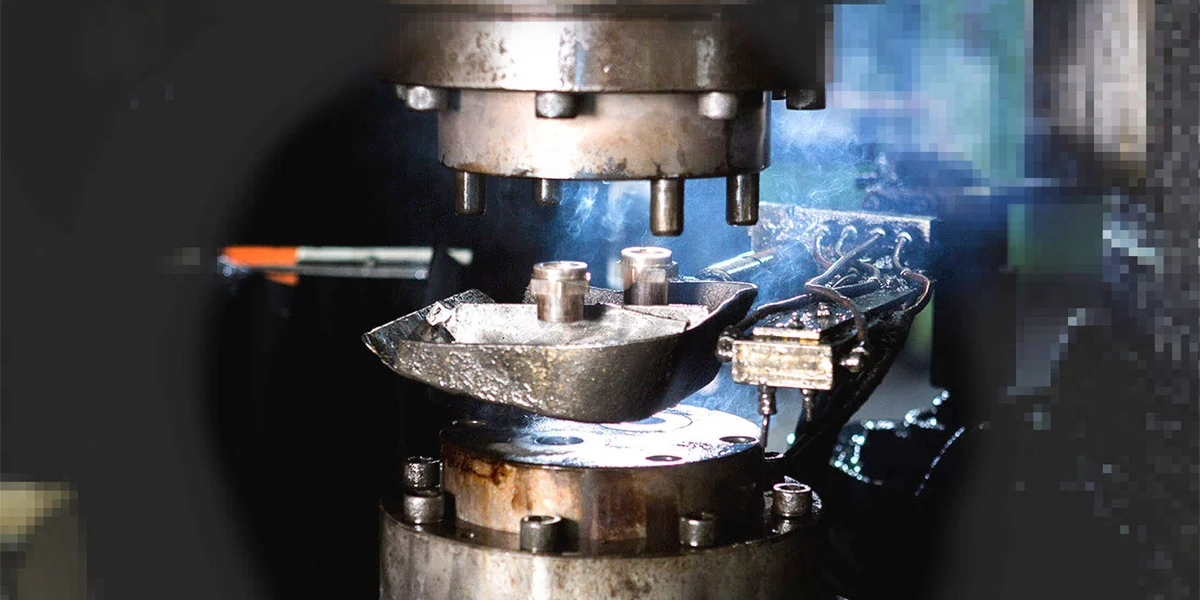

Metal casting begins with the preparation of a mold, which can be made from sand, metal, or other materials depending on the desired outcome. The molten metal is carefully poured into the mold cavity, ensuring that the flow is controlled to prevent defects such as air pockets, shrinkage, or incomplete filling.

One of the primary benefits of metal casting is its versatility in handling various metals, including aluminum, iron, steel, bronze, and copper. Each metal type presents unique challenges and considerations. For example, aluminum casting is valued for its lightweight properties and corrosion resistance, while iron casting is prized for its strength and wear resistance. Understanding these material properties is essential when planning a metal casting project.

Metal casting also involves precise temperature control. The molten metal must be maintained at an optimal temperature to flow properly into the mold and solidify without forming unwanted microstructures or cracks. Advanced casting processes often utilize computer simulations to predict metal flow and cooling rates, ensuring higher accuracy and fewer defects.

Types of Metal Casting Techniques

Several metal casting techniques are widely used in the industry, each with distinct advantages and trade-offs.

Sand Casting

Sand casting is one of the most common methods due to its simplicity and low cost. It involves packing sand around a pattern to create a mold, then pouring molten metal into the cavity. While sand casting allows for large and complex shapes, it may result in rough surface finishes, requiring additional machining.

Investment Casting

Investment casting, also known as lost-wax casting, involves creating a wax pattern coated with a ceramic shell. Once the wax is melted away, molten metal is poured into the shell. This technique is ideal for producing intricate and precise components, often used in aerospace and medical industries.

Die Casting

Die casting uses high-pressure molds made of steel or iron to form metal parts quickly and accurately. It is particularly suited for mass production of small to medium-sized components. Die casting provides excellent surface finish and dimensional accuracy but has higher tooling costs.

Centrifugal Casting

Centrifugal casting involves spinning a mold while pouring molten metal, allowing centrifugal force to distribute the metal evenly. This method is often used for cylindrical components like pipes and rings, ensuring uniform density and strength.

Continuous Casting

Continuous casting is commonly employed in large-scale steel production. Molten metal is continuously poured into a water-cooled mold, solidifying as it moves along a conveyor system. This process improves efficiency and reduces material wastage compared to traditional methods.

Each metal casting technique presents trade-offs between cost, precision, production speed, and material waste. Selecting the appropriate method depends on the specific application and production requirements.

Materials Used in Metal Casting

The choice of metal significantly influences the casting process and the final product’s properties. Common materials used in metal casting include:

- Aluminum: Lightweight, corrosion-resistant, and easy to machine. Ideal for automotive and aerospace parts.

- Iron: Strong and durable, widely used in machinery, construction, and automotive components.

- Steel: Offers high strength and toughness, commonly used in structural components and industrial machinery.

- Copper Alloys: Known for excellent thermal and electrical conductivity, often used in electrical components and decorative items.

- Bronze and Brass: Corrosion-resistant and aesthetically appealing, suitable for artistic and marine applications.

Understanding the thermal properties, melting points, and behavior of each material is essential to prevent casting defects and ensure product quality.

Common Challenges in Metal Casting

While metal molding offers numerous advantages, it also presents challenges that manufacturers must address.

Porosity and Shrinkage

Porosity occurs when air or gases become trapped in the molten metal, creating voids within the casting. Shrinkage happens as metal cools and contracts, potentially leading to cracks or dimensional inaccuracies. Proper mold design, degassing techniques, and controlled cooling can mitigate these issues.

Surface Finish and Tolerances

Achieving a smooth surface finish and precise dimensions can be challenging, especially in sand casting. Additional machining or polishing may be required to meet specifications, which increases production time and cost.

Mold Material Limitations

The choice of mold material affects the casting quality. Sand molds are economical but may limit precision, while metal molds provide higher accuracy but are costly and less flexible for complex shapes.

Temperature Control

Maintaining the correct temperature throughout the casting process is critical. Overheating can lead to metal oxidation and poor mechanical properties, while underheating can result in incomplete filling and weak castings.

By carefully planning and monitoring the casting process, manufacturers can overcome these challenges and achieve consistent, high-quality results.

Applications of Metal Casting

Metal molding is employed across a wide range of industries due to its versatility and efficiency.

Automotive Industry

Metal casting produces engine blocks, transmission housings, and suspension components. Lightweight metals like aluminum are preferred for fuel efficiency, while cast iron provides durability for heavy-duty applications.

Aerospace Industry

The aerospace sector relies on precision casting for turbine blades, structural components, and landing gear parts. Investment casting is particularly valuable due to its ability to produce complex shapes with high accuracy.

Construction and Infrastructure

Metal molding is used to manufacture pipes, valves, machinery, and structural supports. Cast iron and steel components provide strength and longevity for bridges, buildings, and industrial plants.

Electronics and Electrical Industry

Copper and aluminum castings are widely used in electrical components, heat sinks, and connectors due to their excellent conductivity and thermal management capabilities.

Art and Decorative Items

Beyond industrial applications, metal molding is also used for sculptures, jewelry, and decorative hardware. Techniques like investment casting allow for intricate designs and fine detailing.

Advancements in Metal Casting Technology

Modern metal molding has benefited significantly from technological advancements.

Computer-Aided Design (CAD) and Simulation

CAD and simulation software allow engineers to design molds and predict metal flow, cooling patterns, and potential defects before actual production. This reduces trial-and-error, saving time and cost.

Additive Manufacturing Integration

3D printing technology is increasingly used to create molds or patterns for metal molding. This hybrid approach enables more complex geometries and faster prototyping.

Automation and Robotics

Automation in metal molding improves efficiency, safety, and consistency. Robotic pouring and mold handling reduce human error and increase production speed.

Sustainable Practices

Recycling scrap metal and using environmentally friendly mold materials are becoming standard practices. Sustainable metal molding reduces waste, energy consumption, and environmental impact.

These advancements make metal molding more efficient, precise, and environmentally responsible, benefiting both manufacturers and end-users.

Quality Control and Inspection in Metal Casting

Ensuring high-quality metal molding requires rigorous inspection and testing. Common methods include:

- Visual Inspection: Identifying surface defects, cracks, or incomplete filling.

- Dimensional Measurement: Using calipers, coordinate measuring machines, and laser scanning to ensure compliance with specifications.

- Non-Destructive Testing (NDT): Techniques such as X-ray, ultrasonic, and magnetic particle testing detect internal defects without damaging the casting.

- Mechanical Testing: Evaluating tensile strength, hardness, and impact resistance to ensure the casting meets performance requirements.

Quality control is critical for industries where failure can have severe consequences, such as aerospace, automotive, and medical sectors.

The Future of Metal Casting

The future of metal molding is poised for innovation, efficiency, and sustainability. Emerging trends include:

- Advanced Materials: Development of new alloys with superior strength, corrosion resistance, and lightweight properties.

- Smart Casting Processes: Integration of sensors and IoT devices to monitor temperature, flow, and solidification in real-time.

- Energy Efficiency: Adoption of energy-efficient furnaces, recycling systems, and eco-friendly mold materials.

- Customization and On-Demand Production: Combining casting with additive manufacturing allows small-batch, customized production without compromising quality.

These trends ensure that metal molding will continue to evolve, meeting the demands of modern industries while addressing environmental and economic challenges.

Conclusion

Metal molding remains a cornerstone of modern manufacturing due to its versatility, efficiency, and adaptability. By understanding the materials, techniques, and challenges involved, manufacturers can optimize production, reduce costs, and produce high-quality components.

From automotive and aerospace industries to construction, electronics, and art, the applications of metal casting are vast and growing. Technological advancements, including CAD simulations, automation, and sustainable practices, continue to enhance the precision, reliability, and environmental responsibility of casting processes.

Ultimately, metal molding is more than just a manufacturing method; it is a sophisticated process that balances creativity, engineering, and technical expertise. For businesses and industries seeking to create durable, complex, and cost-effective components, metal molding remains an essential and evolving solution.